Wheel Alignment

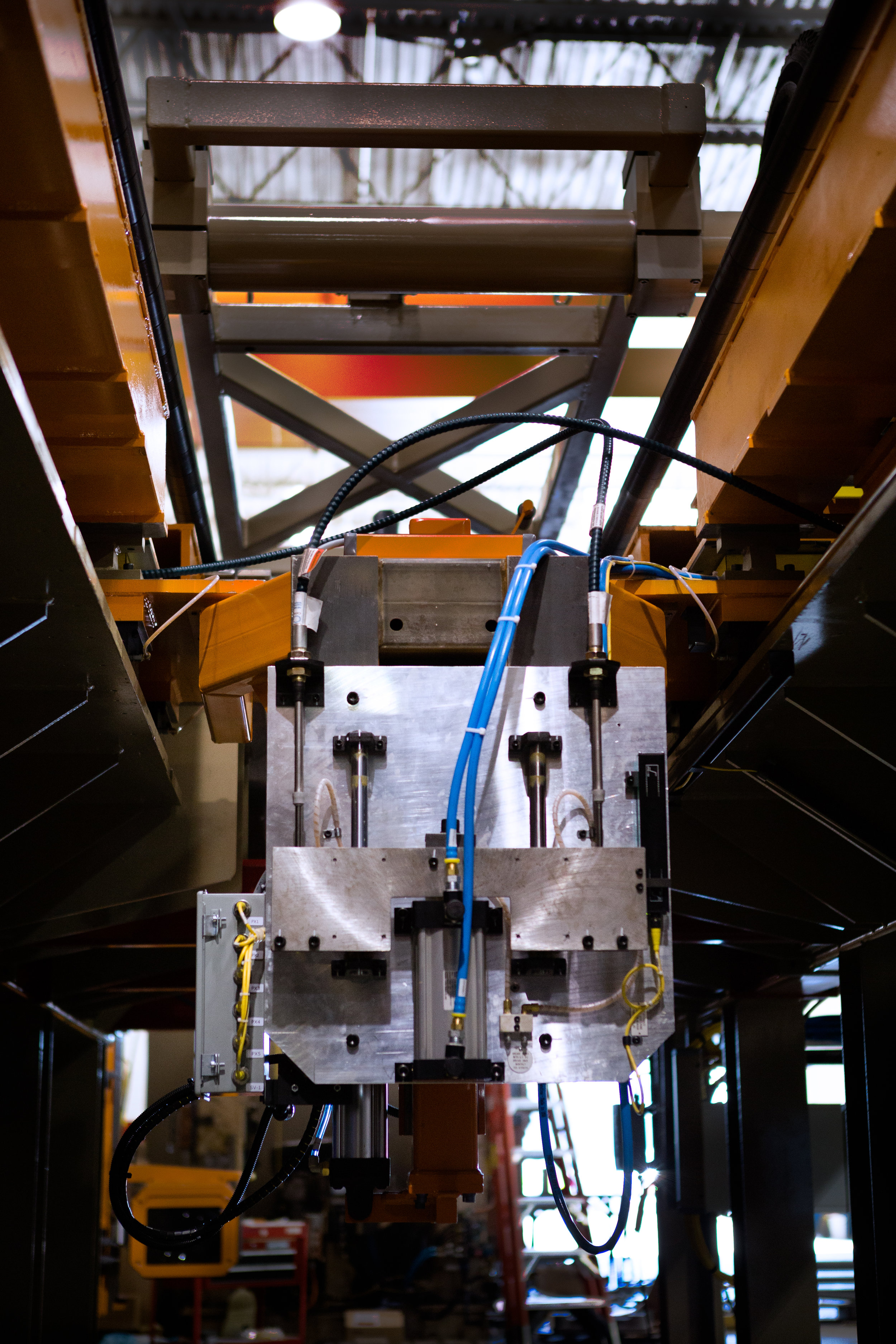

Dominion Technologies Group provides a variety of accurate and dependable Wheel Alignment equipment. The Non-Contact Alignment Machine utilizes digital laser cameras to provide an accurate controlled means to measure toe, camber, and caster values.

The Dominion Technologies Group Non-Contact Wheel Audit Alignment Machine provides a controlled means to check Z-height, Toe, Camber, and Caster settings of new production vehicles just aligned and compare those measurements to plant specifications. The audit alighment machine can accomodate a variety of vehicles with wheelbases ranging from 100.0 inches to 148.0 inches. The audit alignment machine automatically sets itself for the vehicle’s wheelbase based on the vehicle’s barcode signature.

Operation of the audit alignment equipment mechanical assemblies is accomplished using a PLC program. Control of the digital laser cameras, measurements and storage of audit alignment results is done with PC software developed by Dominion’s software engineers. The PC software also communicates with in-plant networks providing vehicle data for quality assurance.

Features

- Adjustable wheelbase with VFD and Absolute Encoder

- Floating Plates with Electric Rollers and Wedge Style Brakes

- Front Retractable Access Decking

- Front and Rear High/Low Pressure Centering

- Front and Rear Tow and Front Camber Laser Cameras

- Fixed Camera Post with Guard

- Drive-On Guide Rollers

- Alignment PC Systems

- Driver Operator Station

- Cycle Start/Complete

Add-Ons

- Automatic Toe Adjust and Set

- Semi-Auto Toe Adjust and Set

- Robotic Toe Adjust and Set

- Caster/Camber Adjust and Set

- Ride Height Adjust and Set

- Indexing Laser Cameras

- Auto/Manual Caster Sweep

- Auto/Manual Steering Wheel Leveling

- Error Checking Steering Leveler Stand

- Vehicle Communication Interface Hardware and Software

- Vehicle Data Collection Hardware and Software

- Torque Monitoring Interface

- Ventilation Interface

- Ticket Printing

- Electronic Power Assisted Steering Calibration